Technical Parameter

Technical Parameter

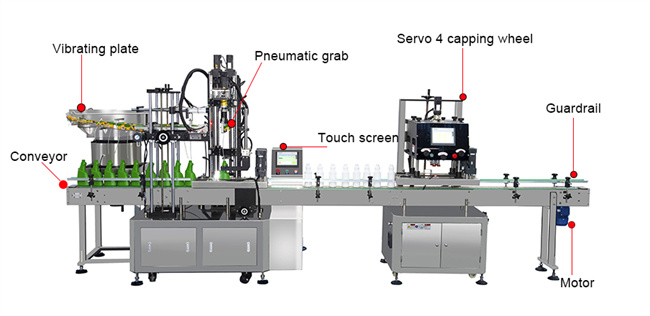

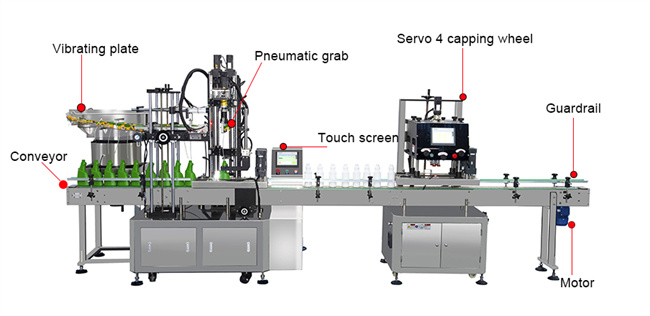

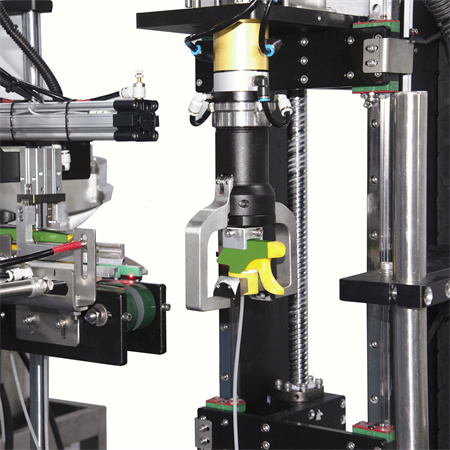

Spray trigger pneumatic screw capping machine

1. Bottle feeding method: manual bottle placement ( or bottle feeding turntable )

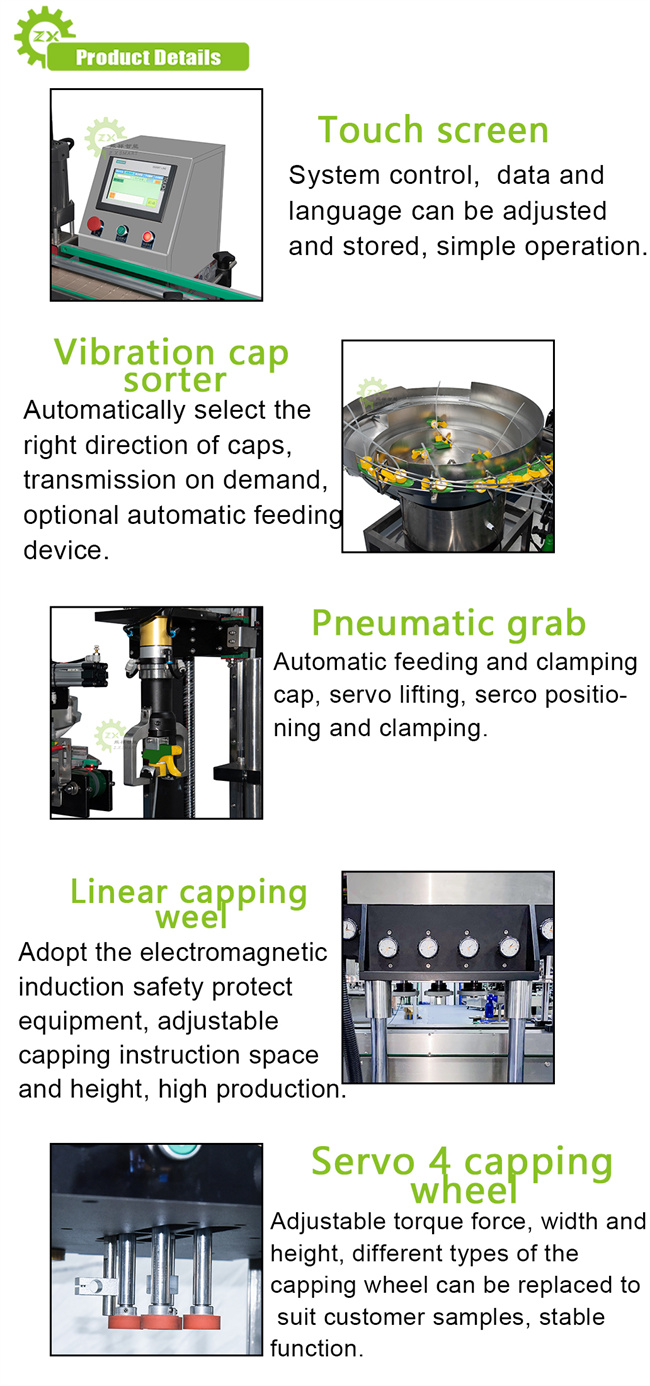

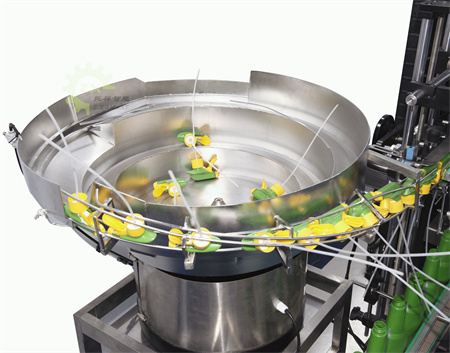

2. Capping method: vibrating disc capping (the vibrating disc needs to be replaced for different bottles) and feeding by elevator

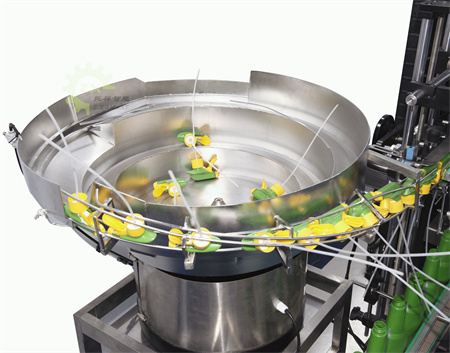

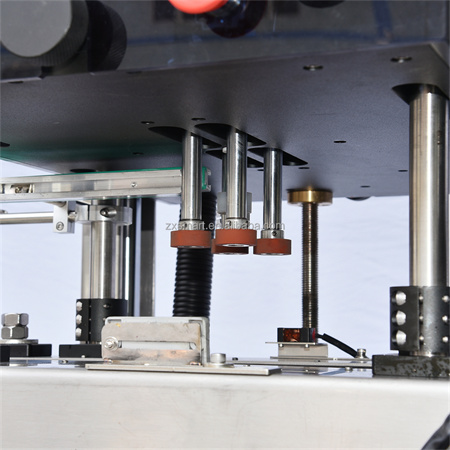

3. Cap feeding mode: pneumatic clamp to take and place the cap

4. Capping form: servo grasping (capping head needs to be replaced for different samples)

5. Capping speed: 20 bottles / min

6. Material: the frame is made of 304# stainless steel

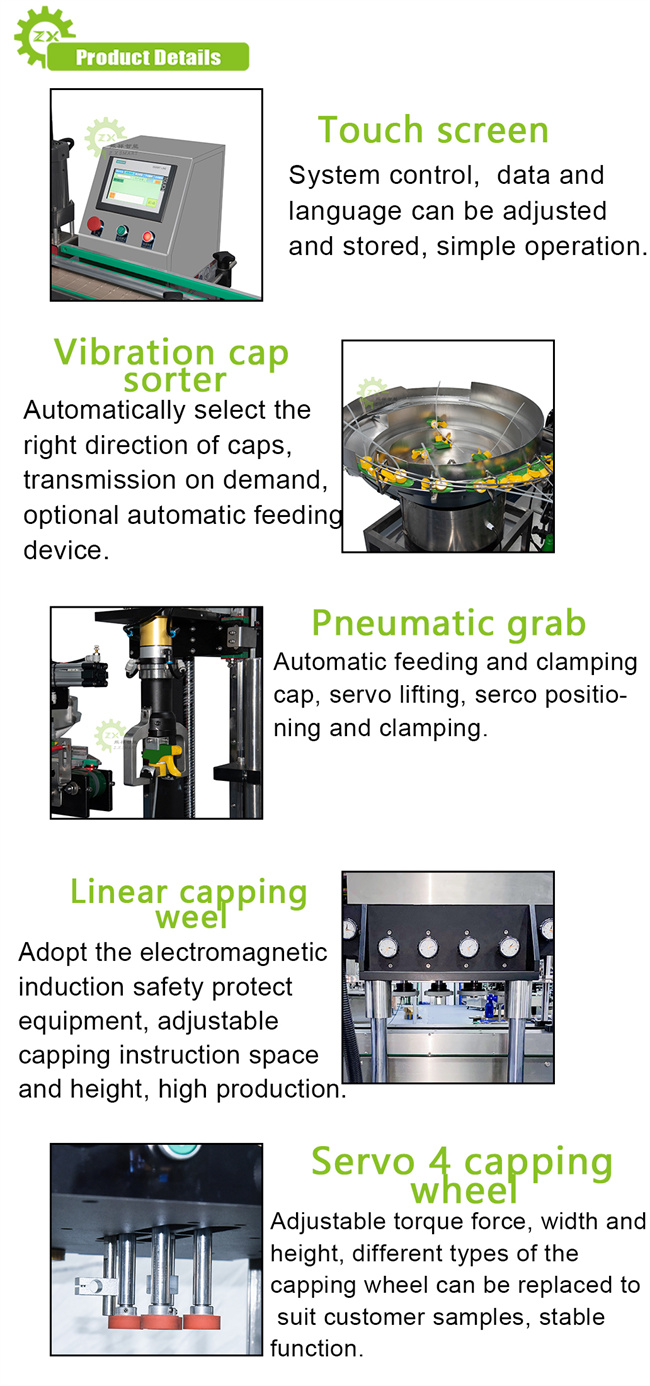

7. Program control: PLC + touch screen

8. Air pressure: 0.6-0.8mpa

9. Conveyor belt: 82mm wide POM chain belt, 800mm ± 25mm above the ground

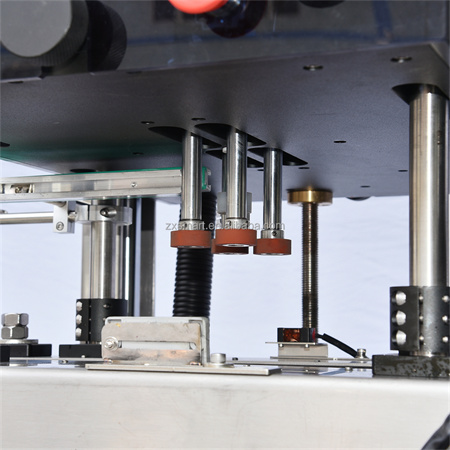

4-wheel servo motor screw capping machine

1. Suitable specification: According to customer samples

2. Cover method:Vibration plate cover

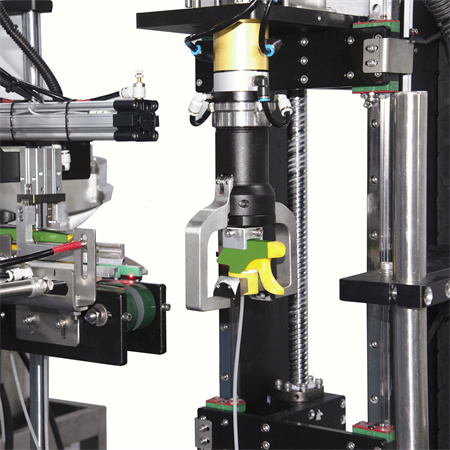

3. Capping form: Servo electric clamp

4. Speed: 2000 BPH

5. Power:About0.2KW

6. power supply:AC220V, 50/60Hz,single-phase

7. Frame material is stainless steel

8. Air pressure:0.6~0.8MPa

Performance characteristics of the whole line

-

The whole line frame, machine feet, etc. are made of corrosion-resistant stainless steel.

-

The capping machine adopts German Siemens PLC and man-machine interface, the program control is convenient and reliable, the operation is simple and convenient.

-

The whole line adopts imported infrared sensor, the position control is more accurate.

-

The pneumatic components of the whole line are made of domestic famous brands, and the quality is reliable.

-

The conveying motor of the whole line adopts high-quality mechanical speed-regulating motor, frequency conversion control, and the speed is more accurate.

-

Guardrails, sensors, positioning cylinders can be easily adjusted in position to adapt to containers of various specifications.