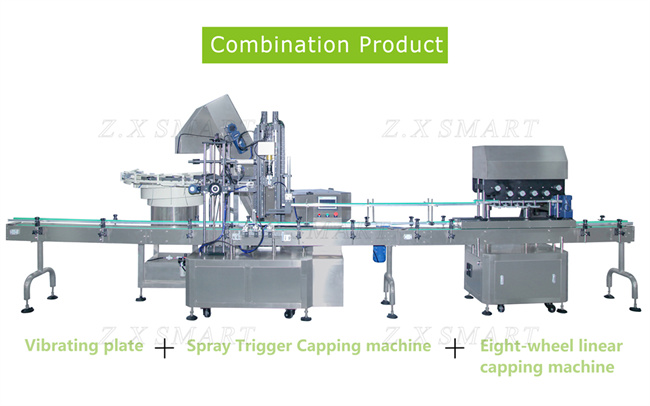

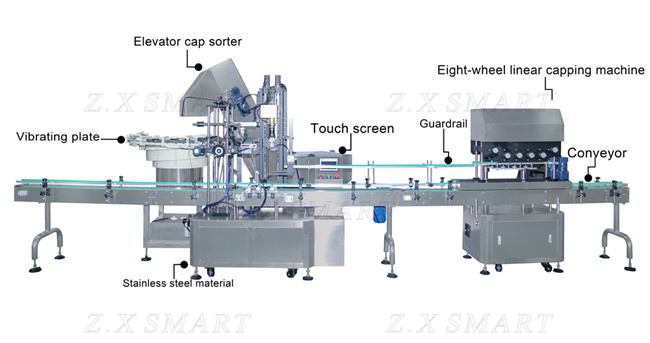

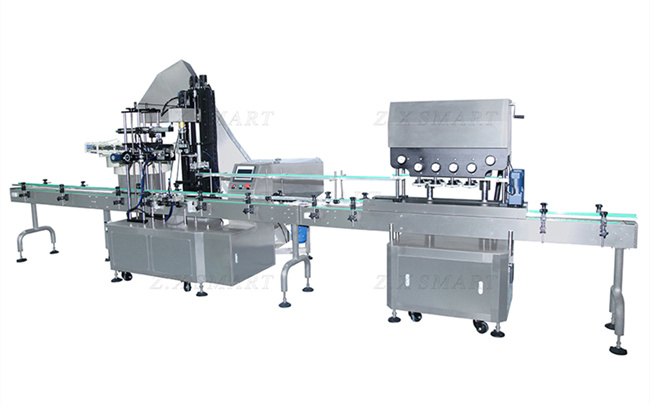

Spray trigger pneumatic screw capping machine

1. Bottle feeding method: manual bottle placement ( or bottle feeding turntable )

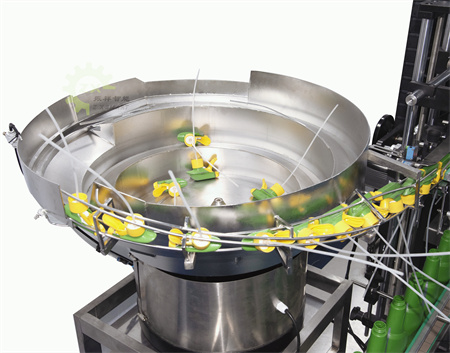

2. Capping method: vibrating disc capping (the vibrating disc needs to be replaced for different bottles) and feeding by elevator

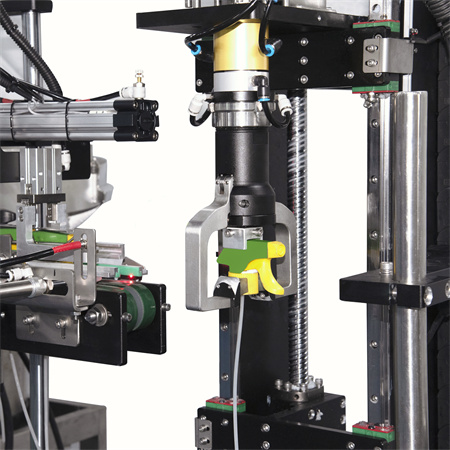

3. Cap feeding mode: pneumatic clamp to take and place the cap

4. Capping form: servo grasping (capping head needs to be replaced for different samples)

5. Capping speed: 20 bottles / min

6. Material: the frame is made of 304# stainless steel

7. Program control: PLC + touch screen

8. Air pressure: 0.6-0.8mpa

9. Conveyor belt: 82mm wide POM chain belt, 800mm ± 25mm above the ground

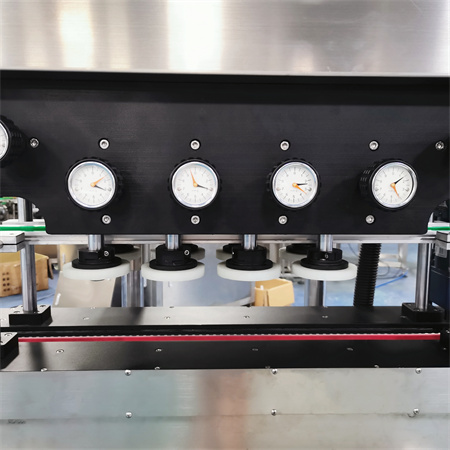

Linear screw capping machine

1. Suitable specification: according to the sample provided by the customer

2. Cover management method: Elevator cap sorter feed caps, hook caps

3. Form of screw cap: 8 wheel set rubbing screw cap

4. Speed: 2000 bottles / hour

5. The frame is made of stainless steel

6. Program control: PLC + touch screen man-machine interface

7. Overall power: about 1.2kW

8. Conveyor belt: 82 mm wide POM chain belt, height 800 ± 25 mm

9. Air pressure: 0.6 ~ 0.8MPa

Main configuration

1. Pneumatic components: Taiwan brand AIRTAC

2. Program controller: German brand Siemens

3. Man machine interface: German brand Siemens 7-inch color touch screen

4. Photoelectric sensor: German brand Leuze

5. Relay and air switch: French brand Schneider

6. Motor frequency converter: German brand Siemens

7. Capping motor: domestic brand motor

8. Materials of exposed parts: stainless steel, anodized aluminum alloy, electroplated 45 steel and plastic parts.